「ありたい姿」実現のために

常に最高の利便性を提供するために優先するのは、売上や利益などの「数値目標」よりも、どんなチカラを持った企業になるべきかの「能力目標」であると考えています。

いつの時代もお客様や社会から必要とされる企業を目指していくために、以下の「ありたい姿」を掲げ、事業に取り組んでまいります。

2030年までに在庫100万アイテムを保有できる企業になりたい。

お客様の利便性向上のために在庫アイテムの拡充と物流システムの強化に取組み、構想を進めているプラネット愛知では今までとは異なるアプローチでの最新の物流システムを構築し、2030年までに在庫100万アイテムを達成できる体制を整えてまいります。

(神奈川県伊勢原市)

1日24時間受注、1年365日出荷できる企業になりたい。

販売店様の利便性向上と今後の商品出荷数増加を見据え、1日24時間受注でき、365日出荷できる体制を整えていきます。2020年8月に建替稼働したプラネット南関東では、配送トラックも進入可能な天井高のある地下駐車場を完備。夜間でも入出庫可能な設備で、24時間稼働が可能な設計になっています。

欠品、誤受注、誤出荷のない企業になりたい。

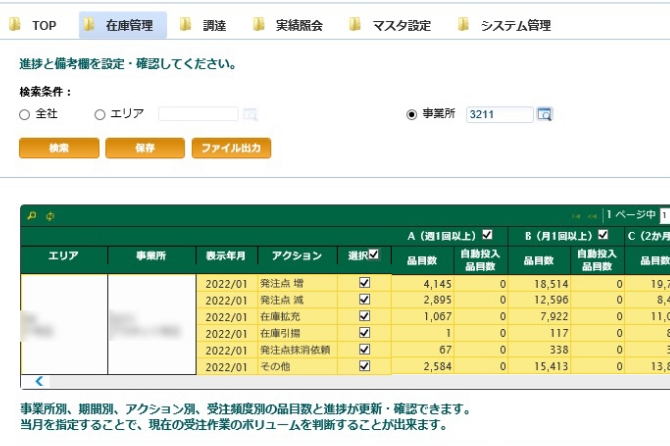

納期遅延の一番の原因は「欠品」にあると考えています。在庫アイテム数の拡充と同時にAIによる適正在庫化へのしくみづくりを進め、欠品を発生させない仕組づくりをしていきます。また受注や出荷の誤りの多くは人が介在する工程で発生します。ロボティクスやAIの導入で自動化・省人化を進め、誤受注、誤出荷のない体制を構築してまいります。

棚卸作業のない企業になりたい。

現在、棚卸作業は年に1度実施していますが、在庫管理システムの高度化により棚卸差異率は0.28%まで削減できています。しかし、61万アイテムの在庫を棚卸作業することは膨大な労力と時間を要します。そのため今後、棚卸作業自体が不要となるように「棚卸全廃委員会」を社内で発足し、その実現のためのシステムや運用の改善を進めています。

問屋であってもユーザー様直送をストレスなくできる企業になりたい。

一般的に、問屋が販売店様からご注文いただいた商品は、販売店様を経由してユーザー様へお届けすることが業界の常識になっています。ただ納期がかかる上に、商品をお届けする際の配送や梱包などが2度実施されることで環境に負荷をかけてしまっています。「ユーザー様直送」では、直接ユーザー様に商品をお届けするため、「納期半減、梱包資材半減、配送運賃半減、環境負荷半減」の実現が可能。「ユーザー様直送」を当たり前の景色にし「環境保全」につなげていきます。

お見積りに瞬時にお応えできる企業になりたい。

販売店様よりいただく1日3万行の見積もりを、AI見積「即答名人」の導入(2020年1月)により最短5秒でのスピード回答を実現。2024年12月末時点での見積自動化率は30.1%で、2025年までには34.0%まで向上させることができるようにシステム改修を続けています。

業界「最速」「最短」「最良」の納品を実現できる企業になりたい。

当社は「即納こそ最大のサービス」と考え、物流システムの強化に取組んでまいりました。今後は、受注から納品までのリードタイム(2024年12月末時点:平均18時間31分45)を1件ごとに分析し、30分単位での短縮を目指します。「即納」を可視化することにより見えてくる課題に取組み、業界「最速」「最短」「最良」の納品を実現できる体制を整えてまいります。

可能な限り環境負担の小さい企業になりたい。

豊富な品揃えと在庫で、ワンストップショッピングを実現することにより、複数の調達先から仕入れるよりも、調達にかかるエネルギーや資源の消費の削減につなげています。 また固定費型物流システムの構築により宅配便のように都度コストをかけずに配送量に関わらず固定のエネルギーで納品。 その他にも、運賃半分、手間半分、環境にも優しい「ユーザー様直送」や納期0(ゼロ)を実現する置き薬ならぬ置き工具「MROストッカー」の拡充を進め、物流に潜むムダを少しずつ解決し、環境負荷の小さい企業を目指します。

リサイクル、リユース、リターナブルにも積極的な

企業になりたい。

1998年から展開している修理工房「直治郎」サービスは使い慣れた工具・設備等を長く使うことで、環境負荷を抑えるとともにコスト削減に貢献することを目的とした独自のサービスです。再研磨や校正だけではなく、テープ加工など幅広いサービスを展開していきます。

日本のモノづくりを支えるプラットフォーマーになりたい。

2021年6月に名古屋大学様と産学連携及びGROUND(株)様、(株)シナモン様との資本業務提携を発表しました。時代の急激な変化の中で信頼できるパートナーとともに、新流通プラットフォーム構築に取組み、モノづくり現場のプロツール調達におけるプラットフォーマーになりたいと考えています。

業界の常識、習慣、定説、定石を塗り替えることのできる企業になりたい。

業界最後発の企業として常に「枠にとらわれない発想」で事業を展開してまいりました。「誰もが思いつき、誰もが進む方向に成功の文字はない」「人の思いつかないことを考え、人のやらないことをやる」。これが企業の活力と成長を生み出し続ける原点です。今後も業界の習慣、定説、定石を塗り替えることができるような常識の不意を突くようなアイデアで、様々な問題を解決していきたいと考えています。